Application of Aluminum Alloys in Aerospace

Aluminum alloys are widely used in the aerospace industry due to their lightweight, high strength, and excellent corrosion resistance. With the continuous advancement of aerospace technology, the demand for materials has been increasing, making the use of aluminum alloys even more crucial.

The density of aluminum alloys is about one-third that of steel, making them an ideal choice in aerospace design. This lightweight characteristic not only reduces the weight of aircraft but also improves fuel efficiency and extends flight range. Additionally, the corrosion resistance of aluminum alloys ensures longevity in various environmental conditions, particularly in high humidity and marine environments.

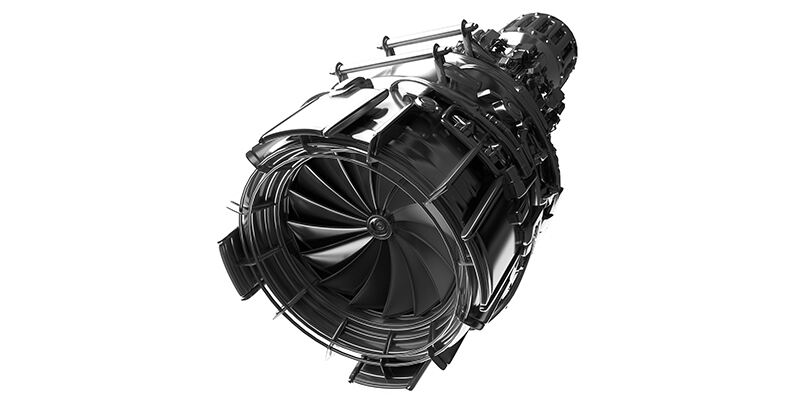

In the aerospace sector, aluminum alloys are primarily used in the manufacture of aircraft fuselages, wings, engine components, and structural parts. For instance, modern aircraft such as the Boeing 787 and Airbus A350 predominantly utilize aluminum alloy materials to achieve lighter and more efficient flight performance.

Moreover, aluminum alloys play a vital role in spacecraft. The shells of rockets, the frames of satellites, and other structural components rely on aluminum alloys to withstand the extreme conditions of launch and the harsh environment of space.

With the continuous progress in aerospace technology, the alloy composition and manufacturing processes of aluminum alloys are also being improved. For example, high-strength aluminum alloys developed in recent years can operate under higher temperatures and pressures, enhancing the overall performance of aircraft. Additionally, advanced manufacturing technologies such as 3D printing allow for more flexible applications of aluminum alloys, enabling the realization of more complex structural designs.

Although the application of aluminum alloys in the aerospace field is already well-established, researchers are still exploring their broader potential. In the future, aluminum alloys may be combined with other materials, such as composites, to create lighter and stronger hybrid structures that meet the demands of the next generation of aerospace vehicles.

In conclusion, the application of aluminum alloys in the aerospace industry not only drives technological advancement but also offers a broad prospect for the future of aerospace endeavors. As materials science continues to develop, the role of aluminum alloys will become increasingly important, aiding humanity in exploring the vast universe.

Typical alloys :2024 2017 2A12 6061 6082 7050 7075 7A04

Available material :Plate, Bars, Pipes, Forgings, Castings