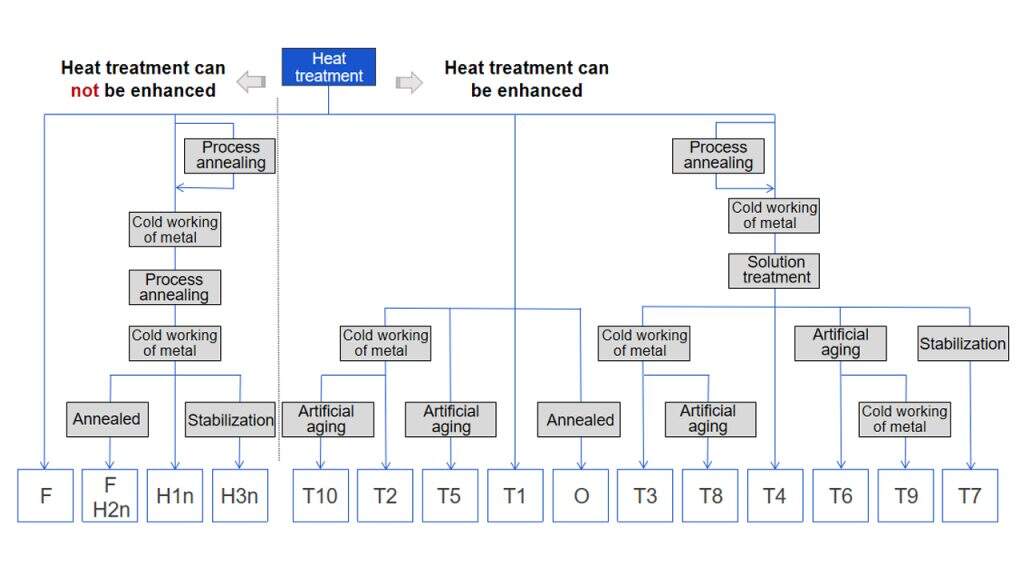

T1 is cooled by a high temperature molding process and then naturally aged to a basically stable state. It is suitable for the products which are no longer cold processed after cooling by high temperature forming process (can be straightened and levelled, but does not affect the mechanical property limit).

T2 is cooled by high temperature forming process, and then aged to a basically stable state after cold processing. It is suitable for cold processing, or straightening and leveling to improve the strength of the products after cooling by high temperature forming process.

T3 solution heat treatment followed by cold processing, and then natural aging to a basically stable state. It is suitable for cold working, or straightening and leveling to improve the strength of the products after the solid solution heat treatment.

T4 solution heat treatment after natural aging to a basically stable state. Suitable for solid solution heat treatment, not cold processing (can be straightened, levelling, but does not affect the mechanical limit) products.

T5 is cooled by a high temperature forming process and then artificially aged. It is suitable for artificial aging products after cooling by high temperature forming process without cold processing (can be straightened and levelled, but does not affect the mechanical property limit).

T6 is a state of artificial aging after solid solution heat treatment. It is suitable for the products which are no longer cold processed after the solid solution heat treatment (can be straightened and levelled, but does not affect the mechanical property limit).

T7 is a state of artificial aging after solid solution heat treatment. It is suitable for the products whose strength exceeds the peak point on the aging curve in order to obtain some important properties after the solid solution heat treatment.

T8 solution heat treatment followed by cold working and then artificial aging. Suitable for cold processing, or straightening, leveling to improve the strength of the product.

T9 solution heat treatment followed by artificial aging, then cold processing state. Suitable for cold processing to improve the strength of the product.

T10 is cooled by the high temperature molding process, cold processing, and then artificial aging state. Suitable for cold processing, or straightening, leveling to improve the strength of the product. T state and TXXX state (other than stress relief state) The TX state code is followed by an additional Arabic numeral (known as TXX state), or two Arabic numeral (known as TXXX state), indicating the state of a particular process that has significantly changed product properties (such as mechanical properties, corrosion resistance, etc.).

T42 is applicable to products whose natural aging has reached a fully stable state after solid solution heat treatment in O or F state. It is also applicable to products whose mechanical properties have reached T42 state after heat treatment of processed products in any state by the demander.

T62 is applicable to products entering artificial aging after solid solution heat treatment in O or F state. It is also applicable to products whose mechanical properties reach T62 state after heat treatment of processed products in any state by the demander.

T73 is applicable to products after solid solution heat treatment, after aging to achieve the specified mechanical properties and stress corrosion resistance indicators T74 and T73 state definition. The tensile strength of this state is greater than that of T73 state but less than that of T76 state.

T76 has the same state definition as T73. The tensile strength of this condition is higher than that of T73 and T74, and the stress corrosion fracture resistance is lower than that of T73 and T74, respectively, but the spalling corrosion resistance is still good.

T7X2 is suitable for the products with mechanical properties and corrosion resistance up to T7X after artificial aging treatment after solid solution heat treatment in O or F state. T81 is suitable for the product after solid solution heat treatment, after about 1% cold working deformation to improve the strength, and then artificial aging. T87 is suitable for the product after solution heat treatment, after about 7% cold working deformation to improve the strength, and then artificial aging. Stress Relief State Add “51,” or “510,” or “511,” or “52,” or “54” to the above TX or TXX or TXXX status code to indicate the product status code that has undergone stress relief treatment.

TX51 TXX51 TXXX51 is suitable for thick aluminum plate, rolled or cold finished bar and die forging, forged ring or rolled ring after cooling in solution heat treatment or self high temperature forming process. These products are no longer straightened after stretching. The permanent deformation of thick plate is 1.5%~3%. The permanent deformation of rolled or cold finished bar is 1%-3%. The permanent deformation of forging ring or rolling ring is 1%~5%. The permanent deformation of extruded rod, mold and pipe is 1%~3%. The permanent deformation of drawn pipe is 1.5%~3%.

TX511 TXX511 TXXX511 is suitable for aluminium extruded rods, shapes and pipes, as well as drawn pipes, which can be slightly straightened to conform to standard tolerances after being cooled in solution heat treatment or self-high-temperature forming processes.

TX52 TXX52 TXXX52 is suitable for solution heat treatment or self-high-temperature forming process after cooling, by compression to eliminate stress, to produce 1%~5%, permanent deformation of the product.usually be used for very thick aluminum plates.

TX54 TXX54 TXXX54 is suitable for die forgings that remove stress by cold shaping within the final forging die. T6, solution treatment (quenching), artificial aging.

T62, annealing or F state solution treatment, artificial aging.

T61 is a special heat treatment condition requiring a strength lower than T6.

Aluminum Alloys that can be heat treated as T tempers are 5000,6000 and 7000 series,Such as 5052 5056 5754 5083 6061 6063 6082 7050 7075 aluminum sheet, aluminum plate,aluminum bar,aluminum rod,aluminum tube pipe and aluminum profile,etc.As a trusted manufacture and stockist,the more widely used T tempers are T4,T6,T651,T652.

Hot News

Hot News2024-12-15

2024-12-12

2024-12-10